Introduction

Have you ever wondered what makes modern technology so powerful and efficient? The answer lies in Neodymium magnets, the strongest permanent magnets commercially available today. As a leading supplier in the magnetic solutions industry, we’ve witnessed firsthand how these remarkable components revolutionize various sectors, from renewable energy to medical devices. Our team has extensive experience working with manufacturers who rely on these magnets for their cutting-edge products. In this comprehensive guide, we’ll explore the essential properties, applications, and best practices for working with Neodymium magnets, ensuring you make informed decisions for your industrial needs.

What are Neodymium Magnets?

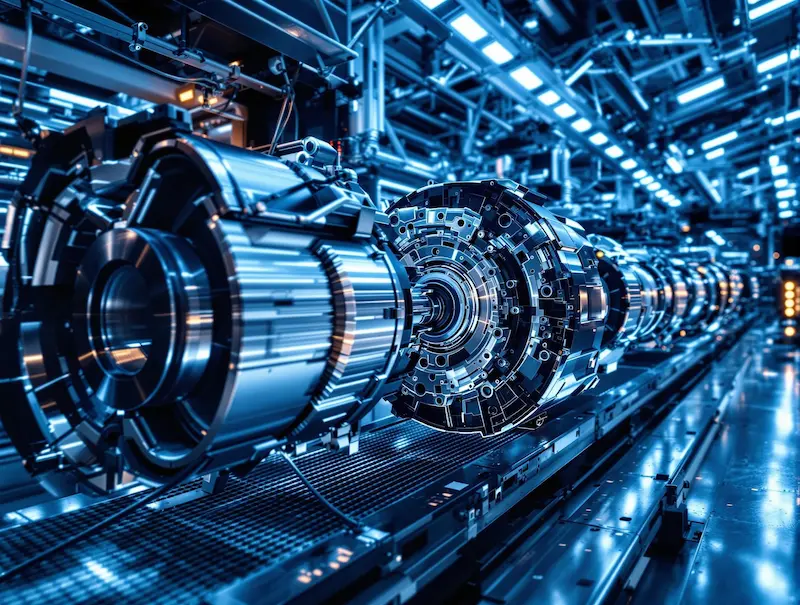

What are Neodymium magnets, and why are they so significant? Neodymium magnets (NdFeB) represent the most powerful type of permanent magnets commercially available today. These rare-earth magnets, composed primarily of neodymium, iron, and boron, have revolutionized numerous industries since their development in the 1980s. Their composition includes neodymium, iron, and boron in specific ratios, allowing them to reach up to 1.4 tesla of magnetic strength. NdFeB magnets are critical for applications in electronics, automotive, and renewable energy sectors. Their exceptional magnetic properties make them invaluable, particularly where compact size and high strength are essential.

Composition and Structure

What is the fundamental composition of Neodymium magnets? The core composition follows the chemical formula Nd2Fe14B. This precise arrangement creates a tetragonal crystalline structure, driving exceptional magnetic properties. The rare earth element neodymium plays a pivotal role in the material’s remarkable strength. Manufacturing involves meticulous control over metallurgical conditions, adopting powder metallurgy techniques and heat treatments to attain optimum properties. This level of precision ensures the integrity and performance of the magnets.

Historical Development

How did the development of Neodymium magnets impact the industry? The creation of NdFeB magnets in 1982 by General Motors and Sumitomo Special Metals marked a substantial breakthrough in magnetic materials. This innovation tackled the limitations of prior magnetic materials, leading to widespread adoption across various industries. The remarkable properties and versatility of Neodymium magnets transformed manufacturing processes, pushing the boundaries of technology in numerous applications.

Practical Considerations

What precautions should be taken while handling Neodymium magnets? Due to their extreme magnetic strength, it’s crucial to handle these magnets with appropriate safety measures. Additionally, they should be stored in controlled environments to maintain their magnetic properties and prevent potential hazards. Consideration of temperature limitations and implementation of proper coating methods for corrosion protection ensures their longevity and performance in different applications.

Exploring Neodymium Magnet Properties

What specific characteristics make Neodymium magnets invaluable? In this chapter, we will delve deeper into the magnetic field strength, temperature coefficients, and practical applications across various sectors. Neodymium magnets are renowned for their high strength and durability, establishing themselves as a critical component in various technological advancements. Understanding these properties allows industries to leverage the full potential of Neodymium magnets, optimizing their use and enhancing overall efficiency in applications.

Here is a structured article composed of multiple chapters on Neodymium magnets:

Understanding Neodymium Magnets

What makes Neodymium magnets the strongest type of permanent magnets? Neodymium magnets possess remarkable magnetic properties that differentiate them from other types of permanent magnets. They offer the highest magnetic field strength, with maximum energy products (BHmax) ranging from 30-52 MGOe and a remanence (Br) of between 1.0-1.4 Tesla. In practical terms, this means that Neodymium magnets deliver powerful performance in compact sizes. Applications across various industries utilize these magnets due to their unique benefits, making them essential for many devices.

Magnetic Strength of Neodymium Magnets

What is the significance of the magnetic strength of Neodymium magnets? The magnetic strength of Neodymium magnets is their most defining characteristic. They exhibit the highest magnetic field strength among permanent magnets, making them ideal for applications where space and size are critical. These magnets can sustain their impressive energy levels, allowing them to perform optimally in various settings, ranging from electric motors to MRI machines. Keeping in mind their potency, they are pivotal in technological advancements across industries.

Temperature Sensitivity

Why is temperature sensitivity an important factor for Neodymium magnets? The performance of Neodymium magnets is sensitive to temperature. They typically operate in a temperature range from 80°C to 200°C, beyond which their performance may suffer. Different grades exist to accommodate various temperature requirements, ensuring that they maintain their magnetic properties under specific conditions. Therefore, understanding their limits is crucial for successful integration into applications.

Coercivity and Stability

What role does coercivity play in the effectiveness of Neodymium magnets? Coercivity refers to a magnet’s resistance to demagnetization. Neodymium magnets have high coercivity values ranging from 750 to 2000 kA/m, which means they maintain their magnetic properties under normal conditions. This aspect is vital for applications in environments with strong opposing magnetic fields. By providing stability, Neodymium magnets ensure reliability in various devices, from speakers to hard drives.

Physical Properties and Handling

Why is careful handling important with Neodymium magnets? Neodymium magnets, while powerful, are also brittle. This characteristic means they require careful handling to avoid chipping or breaking. Additionally, without proper coating, they are susceptible to corrosion. The dense material provides an impressive mass-to-volume ratio, but extra care should be taken during storage and application to prolong their lifespan.

Applications of Neodymium Magnets

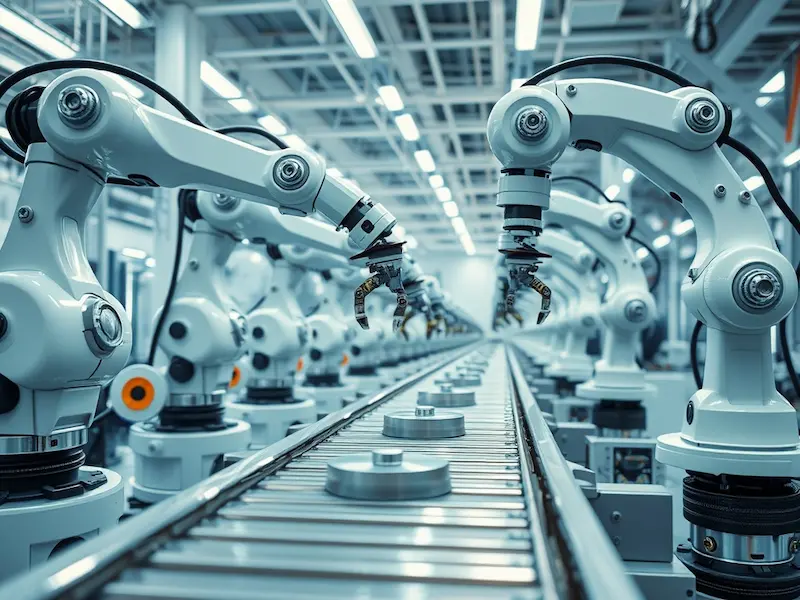

How are Neodymium magnets reshaping modern industrial capabilities? The automotive applications of neodymium magnets have revolutionized various industries, particularly in electric vehicles and advanced manufacturing. These powerful magnets enable enhanced performance efficiency across multiple sectors, from automotive systems to consumer electronics.

Key Takeaways:

- Essential components in electric vehicle motors and sensors

- Critical elements in renewable energy systems

- Vital for miniaturization in consumer electronics

- Fundamental to modern medical imaging equipment

| Industry Sector | Market Share (%) | Growth Rate (Annual) |

|---|---|---|

| Automotive | 35% | 12.5% |

| Electronics | 28% | 9.8% |

| Medical Equipment | 18% | 7.2% |

| Renewable Energy | 19% | 15.3% |

Key Industry Applications

In automotive applications, neodymium magnets serve as crucial components in electric motors, power steering systems, and sensors. Their superior magnetic strength enables manufacturers to design more compact and efficient propulsion systems, directly contributing to enhanced vehicle performance efficiency.

The electronics sector extensively utilizes these magnets in speakers, hard disk drives, and smartphones. Their powerful magnetic properties allow for smaller device footprints while maintaining high performance standards.

“The global neodymium magnet market in automotive applications is projected to grow at a CAGR of 12.5% through 2025, driven primarily by electric vehicle adoption and advanced driver assistance systems.” – Global Market Insights Report 2023

Implementation Considerations

- Evaluate temperature requirements for specific applications

- Consider coating options for corrosion protection

- Assess magnetic field interference with nearby components

- Calculate cost-effectiveness against alternative solutions

Looking ahead to sourcing these essential components, understanding supplier qualifications, pricing structures, and quality control measures becomes crucial for successful implementation in various industrial applications.

Sourcing Neodymium Magnets

What factors should businesses evaluate to ensure optimal sourcing decisions for Neodymium magnets? Selecting reliable suppliers for neodymium magnets requires careful consideration of quality standards, pricing, and production capabilities. The global market features manufacturers primarily based in China, Japan, and Germany, each offering distinct advantages in terms of cost and quality assurance.

Key Takeaways:

- Quality certification requirements (ISO 9001, RoHS)

- Price variations based on grade and quantity

- Lead time considerations for bulk ordering

- Supplier verification and assessment protocols

| Sourcing Region | Market Share (%) | Average Lead Time |

|---|---|---|

| China | 75% | 30-45 days |

| Japan | 12% | 20-30 days |

| Europe | 8% | 15-25 days |

| Others | 5% | 35-50 days |

Supplier Evaluation Criteria

Quality assurance protocols and manufacturing capabilities stand as primary considerations in supplier selection. Established suppliers maintain strict quality control measures and offer detailed material specifications and certifications.

Bulk ordering strategies require careful analysis of minimum order quantities (MOQ) and volume pricing tiers. Organizations should evaluate their projected demand against storage capabilities and cash flow requirements.

“The global neodymium magnet supply chain is experiencing significant shifts, with 85% of manufacturers implementing enhanced quality control measures and sustainable sourcing practices in 2023.” – International Magnetics Association Annual Report

Best Practices for Purchasing

- Request material certificates and test reports

- Establish long-term supplier relationships

- Implement multi-supplier strategy

- Monitor market pricing trends

Moving forward to logistics and delivery considerations, businesses must understand the complexities of shipping magnetic materials and ensuring proper handling throughout the supply chain.

Logistics and Delivery for Neodymium Magnets

How can businesses optimize their logistics processes while maintaining safety and efficiency for neodymium magnets? Ensuring timely delivery of neodymium magnets requires specialized logistics options and robust supply chain management practices. These powerful magnetic materials demand particular attention to packaging, transportation regulations, and handling procedures.

Key Takeaways:

- Specialized packaging requirements for magnetic materials

- International shipping regulations and documentation

- Storage and handling safety protocols

- Supply chain optimization strategies

Transportation Considerations

Safe transportation of neodymium magnets requires proper magnetic shielding and appropriate packaging materials. Carriers must be informed about the magnetic nature of the shipment, and proper documentation must accompany all deliveries.

Supply chain management for magnetic materials involves careful coordination between suppliers, logistics providers, and end-users. Implementation of tracking systems and real-time monitoring ensures visibility throughout the delivery process.

“Proper handling and transportation of neodymium magnets can reduce delivery delays by 40% and minimize damage risks by 60%, according to recent industry studies.” – International Logistics Safety Council

Safety Protocols

Storage facilities must maintain specific conditions to preserve magnetic properties and prevent unwanted interactions. Temperature-controlled environments and proper spacing between magnetic materials are essential considerations for warehouse management.

Best Practices for Logistics Management

- Implement magnetic-safe packaging protocols

- Use specialized carriers familiar with magnetic material transport

- Maintain detailed tracking and documentation systems

- Establish clear handling procedures for all supply chain partners

As we conclude this guide to neodymium magnets, we’ll summarize the key points covered throughout these chapters and provide final recommendations for successful implementation in your business operations.

Conclusions

Neodymium magnets represent the pinnacle of permanent magnetic technology, offering unmatched strength with energy products up to 52 MGOe. Their development in the 1980s revolutionized multiple industries, from automotive to medical devices. These magnets’ unique composition of neodymium, iron, and boron (Nd2Fe14B) enables their exceptional performance, though careful handling is required due to temperature sensitivity and brittleness. The global market is dominated by Asian manufacturers, with China holding 75% market share. Proper sourcing, logistics, and safety protocols are crucial for successful implementation. As technology advances, particularly in electric vehicles and renewable energy, the demand for neodymium magnets continues to grow, making them an indispensable component of modern industrial innovation.

FAQ

Question1: What are Neodymium magnets and why are they important in B2B applications?

Answer1: Neodymium magnets, also known as NdFeB magnets, are the strongest type of permanent magnet available. They are crucial in B2B applications due to their high strength, durability, and long-lasting magnetic properties, making them ideal for various industrial, commercial, and technical uses.

Question2: What are the basics of Neodymium magnets that B2B buyers should know?

Answer2: Neodymium magnets are made from an alloy of neodymium, iron, and boron. They are known for their high magnetic strength, resistance to demagnetization, and compact size, which makes them up to 10 times stronger than other types of magnets. This basics understanding is essential for B2B buyers researching new products.

Question3: How do the high strength and magnetic properties of Neodymium magnets benefit B2B industries?

Answer3: The high strength and magnetic properties of Neodymium magnets enable the miniaturization of components, improve efficiency in motors and generators, and enhance performance in applications such as audio speakers, MRI machines, and electric vehicles. These benefits are particularly valuable for manufacturers, engineers, and product developers.

Question4: What is an introduction to Neodymium magnets for B2B professionals?

Answer4: Neodymium magnets are a versatile and powerful tool used in various industries, including automotive, electronics, medical devices, and renewable energy. They are essential for B2B professionals due to their ability to provide strong magnetic fields in compact sizes, making them integral in numerous applications.

Question5: Where can B2B buyers find industry-specific product pages and suppliers for Neodymium magnets?

Answer5: B2B buyers can find industry-specific product pages and suppliers for Neodymium magnets through reputable online suppliers such as MagnetShop.com, TotalElement, and KJ Magnetics. These websites provide detailed product information, bulk ordering options, and fast delivery services.

Question6: Why do B2B buyers research Neodymium magnets, and what benefits are they looking for?

Answer6: B2B buyers research Neodymium magnets to understand their benefits, such as high strength, durability, and long-lasting magnetic properties. They seek clarity on how these magnets can enhance their products’ performance, efficiency, and reliability. This research is crucial for making informed purchasing decisions.

Question7: How can Neodymium magnets be used by manufacturers, engineers, and product developers in their projects?

Answer7: Manufacturers, engineers, and product developers can use Neodymium magnets in a wide range of applications, including electric motors, generators, magnetic resonance imaging (MRI) devices, audio speakers, and wind turbine generators. These magnets offer high strength and stability, making them ideal for various industrial and commercial projects.

Question8: What are the bulk ordering options and delivery considerations for Neodymium magnets in B2B transactions?

Answer8: B2B buyers can take advantage of bulk ordering options for Neodymium magnets from suppliers, which often include fast delivery services. This is particularly beneficial for businesses that require large quantities of magnets for their operations, ensuring timely and efficient supply chain management.

External Links Recommendation

- Common Applications of Neodymium Magnets

- Applications for Permanent Magnets

- The Wide Variety of Applications for Neodymium Magnets

- Common Uses for Neodymium Magnets

- 8 Common Applications of Neodymium Ring Magnets

- Neodymium Magnets in Industrial and Commercial Applications

- Benefits of Neodymium Magnets for B2B Buyers

- Bulk Ordering and Fast Delivery Options for Neodymium Magnets