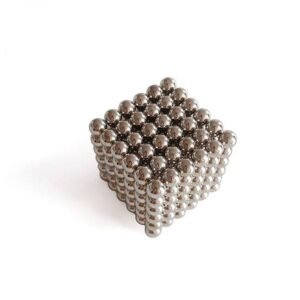

Block Magnets

Neodymium Magnets N52

The main components are rare earth elements Neodymium (Nd), iron (Fe), and boron (B). Its main raw materials include neodymium about 30%, iron about 65%

Additional information

| Model Number | FGRM |

|---|---|

| Size | Customized |

| Magnetizing Direction | Smallest Thickness |

| Shape | Block |

| Composition | Neodymium, Iron, Boron, Other elements |

| Grade | N33-N52,N35M-N48M,N33H-N46H,N33SH-N44SH,N30UH-N38UH,N30EH-N35EH |

| Coating | Ni-Cu-Ni coating(Nickel coating) |

| Tolerance(mm) | ±0.1 |

| Salt Spray Test(hour) | 48 |

| Working Temperature | Max. 80 C° to 200 C° |

Product Details:

Neodymium magnet is also called” NdFeB magnet, or rare earth magnets”, which is based on Nd2Fe14B. The main components are rare earth elements Neodymium (Nd), iron (Fe), and boron (B). Its main raw material is rare earth metal neodymium about 30%, metallic element iron about 65%, non-metallic element boron about 1% and other elements.

-How did Neodymium magnets occurred?

-The General Motors and Sumitomo Special Metals initially founded Nd2Fe14B compound in 1984, before this magnet, companies have to use more expensive SmCo permanent magnets for motors. General Motors finally invented bonded Neodymium magnets, and Smitomo Special metals invented sintered Neodymium magnets. What we sell is mainly sintered Neodymium magnets.

-Application: electric motors, speakers, electronics, medical equipment, wind turbines, aerospace, toys, magnetic tools and other fields.

-Main Process flow: raw material – smelting ingot/spinning belt – powder making – profiling – sintering – grinding – cutting – electroplating – finished product.

-Main Testing: dimensions Inspection, gauss test, magnetic flux test, magnetic property test, salt spray test, coating thickness test, pulling force test.