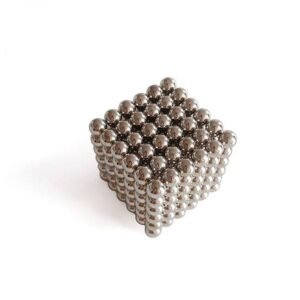

Disc Magnets

Neodymium magnet is also called” NdFeB magnet, or rare earth magnets”, which is based on Nd2Fe14B. The main components are rare earth elements Neodymium (Nd)

Additional information

| Model Number | FGRM |

|---|---|

| Size | Customized |

| Magnetizing Direction | Axially |

| Shape | Disc |

| Composition | Neodymium, Iron, Boron, Other elements |

| Grade | N33-N52,N35M-N48M,N33H-N46H,N33SH-N44SH,N30UH-N38UH,N30EH-N35EH |

| Coating | Ni-Cu-Ni coating(Nickel coating) |

| Tolerance(mm) | ±0.1 |

| Salt Spray Test(hour) | 48 |

| Working Temperature | Max. 80 C° to 200 C° |

Product Details:

Neodymium magnet is also called” NdFeB magnet, or rare earth magnets”, which is based on Nd2Fe14B. The main components are rare earth elements Neodymium (Nd), iron (Fe), and boron (B). Its main raw material is rare earth metal neodymium about 30%, metallic element iron about 65%, non-metallic element boron about 1% and other elements.

There are usually several common shapes for these strong Neodymium magnets, such as disc magnet, block magnet, ring magnet and arc magnet. Almost all products are customized per dimensions or drawings from customer, usually an inquiry shall include these content: grade, dimension, tolerance, coating and magnetization direction. About magnetic property, there are usually N33 to N52, N35M to N48M, N33H to N46H, N33SH to N44SH, N30UH to N38UH, N30EH to N35EH etc. About coating, there are usually Ni-Cu-Ni(Nickel), Zn and Epoxy coating etc. These coating can protect magnets from rust. There are usually axially magnetized and diametrical magnetized. Our standard tolerance is ±0.05mm and ±0.10mm.

-Neodymium magnets have higher remanence, much higher coercivity and energy product, but often lower Curie temperature than other types of magnets

-Application: electronics, electric machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields.

Main Process flow: raw material – smelting ingot/spinning belt – powder making – profiling – sintering – grinding – cutting – electroplating – finished product.

Main production equipment: smelting furnace, belt spinning furnace, jaw breaking machine, jet mill, compression molding machine, vacuum packaging machine, isostatic press, sintering furnace

Main machining equipment: centerless grinding, double-end grinding, flat grinding, slicer, double-sided grinding, wire cutting, bench drill, special-shaped grinding, etc.